Wholesale Lead Management Software Factory – Reference Material For Physical Testing – Shandong Institute of Metallurgical Science

Wholesale Lead Management Software Factory – Reference Material For Physical Testing – Shandong Institute of Metallurgical Science Detail:

Each coal was air dried, reduced in size to <0.2mm, homogenized and packaged into individual bottled units.

Table 1 Certified values and Uncertainty for coal July-01-2021 to June -30-2022

|

GBW No. |

Production Batch |

Certified Value& Uncertainty |

Sulfur St,d/% |

Ash Ad/% |

Volatile Matter Vd/% |

Gross Calorific Value Qgr,d MJ/kg |

Carbon* Cd /% |

Hydrogen* H d /% |

Nitrogen* Nd /% |

True Relative Density (20℃) *

|

Characteristic of Char Residue*(CRC) |

Coal Type |

|

GBW11101 |

L |

Certified Value |

0.45 |

10.53 |

20.17 |

31.96 |

79.24 |

4.22 |

1.36 |

1.40 |

6 |

Bituminous |

|

Uncertainty |

0.03 |

0.07 |

0.22 |

0.16 |

0.38 |

0.10 |

0.04 |

0.02 |

||||

|

GBW11102 |

c |

Certified Value |

1.59 |

9.70 |

34.48 |

30.17 |

73.46 |

4.65 |

1.36 |

1.41 |

5 |

Bituminous |

|

Uncertainty |

0.03 |

0.12 |

0.25 |

0.16 |

0.27 |

0.17 |

0.05 |

0.02 |

||||

|

GBW11104 |

m |

Certified Value |

1.03 |

17.57 |

8.07 |

27.77 |

74.71 |

2.26 |

0.84 |

1.69 |

2 |

Anthracite |

|

Uncertainty |

0.02 |

0.12 |

0.20 |

0.11 |

0.22 |

0.10 |

0.04 |

0.03 |

||||

|

GBW11105 |

j |

Certified Value |

1.74 |

16.86 |

7.86 |

27.98 |

74.73 |

2.37 |

0.98 |

1.67 |

2 |

Anthracite |

|

Uncertainty |

0.03 |

0.14 |

0.19 |

0.15 |

0.27 |

0.07 |

0.03 |

0.02 |

||||

|

GBW11107 |

g |

Certified Value |

0.81 |

9.34 |

30.53 |

31.03 |

76.17 |

4.58 |

1.37 |

1.39 |

6 |

Bituminous |

|

Uncertainty |

0.02 |

0.09 |

0.30 |

0.15 |

0.26 |

0.09 |

0.02 |

0.02 |

||||

|

GBW11107 |

i |

Certified Value |

0.82 |

9.05 |

30.54 |

31.12 |

76.32 |

4.54 |

1.38 |

1.40 |

6 |

Bituminous |

|

Uncertainty |

0.03 |

0.11 |

0.29 |

0.17 |

0.27 |

0.11 |

0.03 |

0.03 |

||||

|

GBW11108 |

t |

Certified Value |

1.91 |

13.33 |

32.97 |

28.34 |

69.55 |

4.39 |

1.19 |

1.45 |

5 |

Bituminous |

|

Uncertainty |

0.03 |

0.11 |

0.20 |

0.16 |

0.23 |

0.14 |

0.05 |

0.03 |

||||

|

GBW11109 |

s |

Certified Value |

2.83 |

31.30 |

29.21 |

21.82 |

53.18 |

3.66 |

0.93 |

1.62 |

5 |

Bituminous |

|

Uncertainty |

0.05 |

0.17 |

0.26 |

0.22 |

0.39 |

0.10 |

0.03 |

0.02 |

||||

|

GBW11109 |

u |

Certified Value |

2.57 |

30.89 |

28.26 |

22.24 |

54.04 |

3.72 |

0.91 |

1.62 |

6 |

Bituminous |

|

Uncertainty |

0.06 |

0.17 |

0.28 |

0.22 |

0.48 |

0.13 |

0.03 |

0.02 |

||||

|

GBW11110 |

q |

Certified Value |

4.35 |

28.92 |

20.47 |

22.91 |

56.99 |

3.23 |

0.94 |

1.66 |

4 |

Bituminous |

|

Uncertainty |

0.06 |

0.17 |

0.29 |

0.16 |

0.39 |

0.08 |

0.03 |

0.02 |

||||

|

GBW11110 |

r |

Certified Value |

4.13 |

33.96 |

24.35 |

20.70 |

51.00 |

3.25 |

0.99 |

1.72 |

4 |

Bituminous |

|

Uncertainty |

0.07 |

0.20 |

0.31 |

0.19 |

0.40 |

0.09 |

0.04 |

0.02 |

||||

|

GBW11111 |

u |

Certified Value |

1.73 |

15.72 |

23.54 |

29.26 |

72.07 |

4.14 |

1.18 |

1.45 |

6 |

Bituminous |

|

Uncertainty |

0.05 |

0.10 |

0.27 |

0.14 |

0.42 |

0.08 |

0.04 |

0.02 |

||||

|

GBW11112 |

L |

Certified Value |

2.15 |

22.09 |

9.55 |

25.64 |

68.65 |

2.30 |

0.87 |

1.73 |

2 |

Anthracite |

|

Uncertainty |

0.06 |

0.13 |

0.31 |

0.15 |

0.39 |

0.09 |

0.04 |

0.02 |

||||

|

GBW11113 |

L |

Certified Value |

3.42 |

16.18 |

11.99 |

28.68 |

72.56 |

3.28 |

1.03 |

1.53 |

2 |

Anthracite |

|

Uncertainty |

0.05 |

0.12 |

0.27 |

0.15 |

0.42 |

0.08 |

0.04 |

0.02 |

||||

|

GBW11113 |

m |

Certified Value |

3.37 |

16.06 |

12.10 |

28.68 |

72.51 |

3.31 |

1.03 |

1.53 |

2 |

Anthracite |

|

Uncertainty |

0.06 |

0.12 |

0.30 |

0.17 |

0.35 |

0.07 |

0.04 |

0.02 |

||||

|

GBW11126 |

g |

Certified Value |

0.27 |

9.49 |

8.14 |

32.21 |

83.28 |

3.16 |

1.15 |

1.47 |

2 |

Anthracite |

|

Uncertainty |

0.02 |

0.12 |

0.19 |

0.10 |

0.28 |

0.06 |

0.04 |

0.01 |

Note: * Indicates that it is not within the recommended scope for production proficiency of CNAS

The homogeneity test was done on the bottled units by determination of ash and sulfur. The minimum weight of sample taken for analysis is 1.0g (ash) or 0.05g (sulfur). Variance analysis showed that the variability among different bottles was not significantly different from the variability between replicate determinations.

The validation of the certified values is one year. The certification will be performed for every year once revised certified values can be issued on application by Shandong Institute of Metallurgical Science Co., Ltd.

Characterization of methods using two or more methods of demonstrable accuracy in 9 competent laboratories.

|

Item |

Analysis method |

|

Total sulfur |

GB/T 214-2007 Determination of total sulfur in coal, Eschka method |

|

Ash and Volatile matter |

GB/T 212-2008 Proximate analysis of coal |

|

Gross calorific Value |

GB/T 213-2008 Determination of calorific value of coal |

|

Carbon and Hydrogen |

GB/T 476-2008 Determination of carbon and hydrogen in coal |

|

Nitrogen |

GB/T 19927-2008 Determination of nitrogen in coal |

|

True Relative Density |

GB/T 217-2008 Determination of true relative density of coal |

The certification analyses were performed using the Chinese National Standard (GB) methods by several qualified laboratories.

The certified value was expressed as XT±U, where XT is the mean value and U is the expanded uncertainty (95% confidence level). The uncertainty actually given in table 1 includes allowance for sample degradation within one year.

The statistical analysis and overall direction and coordination of the technical measurements leading to certification were performed by Shandong Institute of Metallurgical Science Co., Ltd.

Before characterization of 9 qualified laboratories, the instruments and equipment used shall be verified or calibrated, and certified reference materials shall be used for monitoring during characterization to ensure the traceability of reference materials.

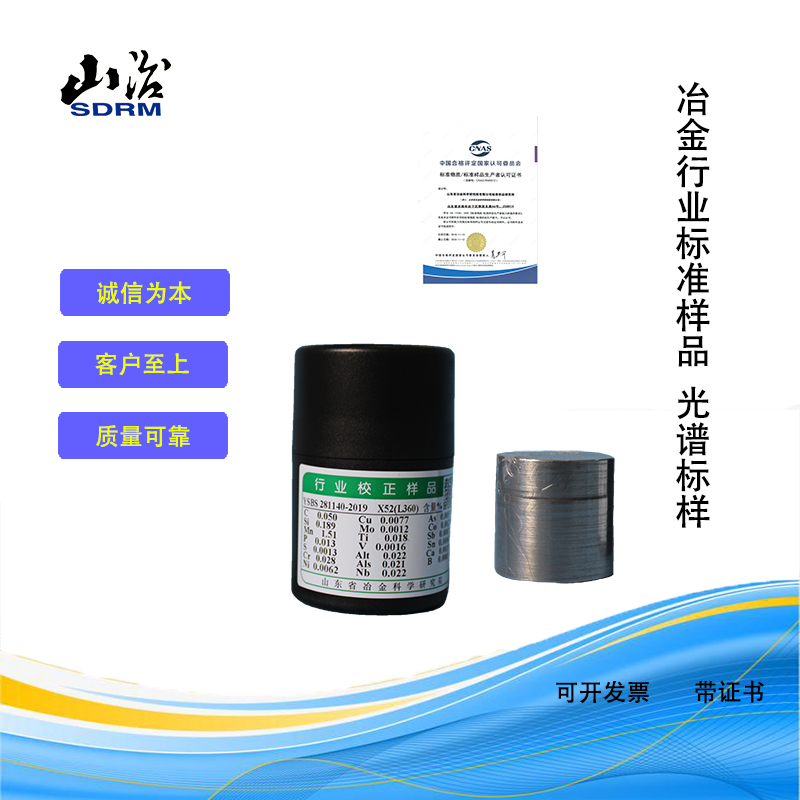

1) These certified reference materials are packed in a brown glass bottle. Each weights 50g.

2) The bottle containing the materials must be kept tightly stopped and stored in cold and dry place, and opened only when necessary.

3) All data are expressed on dry bases. The moisture (moisture in the general analysis test sample) used for calculating the data on dry bases are determined according to moisture analysis method in GB/T 212-2008 “Proximate Analysis of Coal”.

4) The values given in table 1 of this certificate are those determined on July-01-2021 for CRM.

Product detail pictures:

Related Product Guide:

"Quality to start with, Honesty as base, Sincere company and mutual profit" is our idea, as a way to build constantly and pursue the excellence for Wholesale Lead Management Software Factory – Reference Material For Physical Testing – Shandong Institute of Metallurgical Science , The product will supply to all over the world, such as: Egypt, moldova, Venezuela, We've established long-term, stable and good business relationships with many manufacturers and wholesalers around the world. Currently, we've been looking forward to even greater cooperation with overseas customers based on mutual benefits. You should feel free to contact us for more details.

Perfect services, quality products and competitive prices, we have work many times, every time is delighted, wish continue to maintain!